Apex Fiber Core Basalt Fiber Insulation

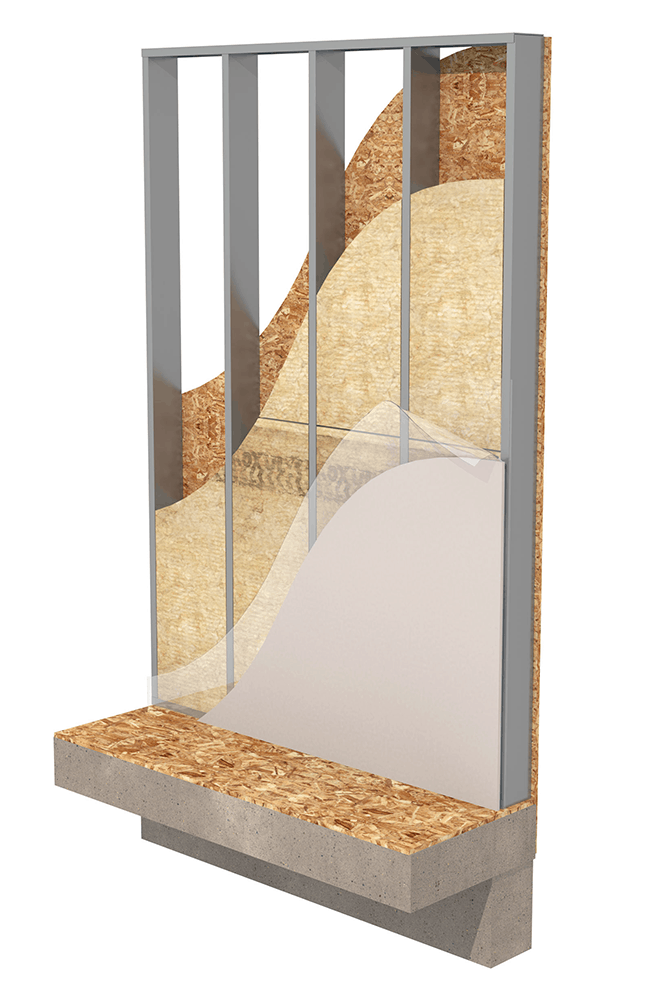

Apex’s Fiber core non-structural insulation is non-combustible, vapor permeable, water repellent and sound absorbent insulation. It is used within wall cavities in both steel and wood framed construction and provides higher insulation values than conventional fiber glass insulation. Fiber Core insulation is highly sound attenuating, does not propogate mold, does not retain water if exposed and is an excellent fire stop.

What is Fiber Core insulation?

Fiber Core insulation is a rigid board insulation which provides excellent R-value per inch, roughly R4.1 and provides a defineable benefit in energy saving over conventional insulation. Apex’s Fiber Core insulation provides extremely good sound insulation which create more acoustically comfortable living environments by keeping sound contained. During exposure to fire Fiber Core insulation won’t burn or melt, unlike fiber glass insulation and keeps its integrity and serviceability through such an event. The hydrophobic nature of Fiber Core means it does not remain wet, sag or otherwise change dimensionally if exposed to water and unlike fiber glass insulation, Fiber Core does not significantly lose performance or hold water wicking to nearby building materials. Therefore, Fiber Core retains its insulation value and allows the surrounding structure to dry. Fiber Core is inorganic containing no volatile Organics and does not propogate mold and is not attractive to bugs as a food source.

How It's Made

Fiber Core Basaltic fiber insulation is spun from molten stone at about 1600 degrees C and the resulting fibers are collected and processed to form a complex matrix of stone fiber and air laid up in rigid boards of various thicknesses. Basalt fibers are tough fibers often used in reinforcing of concrete and as components in industrial compounds. The material is totally inorganic and does not impact the environment if disposed in land fill. Because Fiber Core is made of strands of minerals, either from abundant rock or the recycled slag from iron-ore blast furnaces, the EPA requires that mineral wool contain at least 70 percent recycled content by weight, second only to cellulose. The proportion of recycled materials in Fiber Core can surpass 90 percent. Fiber Core insulation is a green, eco-friendly, highly insulative product which is suitable for use where any conventional insulation is used with the added security of its noncombustable fire stopping properties.

Addressing Energy Code

Heating and cooling of living spaces consumes 44 percent of all energy used in the home, according to the Department of Energy. Fiber Core insulation can reduce the annual heating and cooling bill 30 percent over conventional construction. With the average U.S. household spending about $650 per year on heating and cooling, the investment in higher quality insulation can pay off quickly.

Over the lifespan of a home, the energy saved with a well-insulated building envelope far outweighs the environmental impact of insulation’s manufacture. The North American Insulation Manufacturers Association states that the insulation produced annually in the United States saves 12 times the energy its manufacture consumes. Although this calculation may ignore the energy required to extract and process materials used to make insulation, it gives you an idea of how much energy insulation can save.

When comparing two materials of equal performance, consider the environmental impact of each product’s manufacture and disposal. Fiber Core insulation is made from nontoxic, abundant and renewable materials, while others are made from limited petroleum resources and are difficult or impossible to recycle. Insulation materials can affect indoor air quality, and if improperly installed, to a great degree. People with chemical sensitivities should check their response to a product before installing it. Concerns that may arise include irritation from airborne fibers and emissions from glues,flame retardants or other additives, especially if they are bioaccumulative. Fiber Core insulation is nontoxic and does not contain any volatile organics or formaldehyde.